Hello guys, today we are going to discuss an aspect so often over-looked, heat management.

In this post, our primary focus will be on turbocharged engines. While naturally aspirated engines do also need to manage their heat effectively, it becomes far more complex and critical when dealing with forced induction engines. The challenges associated with heat management in turbocharged engines require special attention to ensure optimal performance and reliability, especially in hard driving conditions.

Compressed air heat

Turbocharging utilises a compressor wheel to force more air into the engine's cylinders. The compressor and turbine wheels are connected by a shaft, and the turbine wheel is propelled by the exhaust gases as they exit the engine. While turbocharging can provide substantial increases in power output, it also creates a huge amount of heat in the process.

When air is compressed by the turbocharger the temperature of the air rises significantly. If this hot, compressed air is then sent directly into the engine it can massively reduce engine efficiency.

To combat this, we can use intercoolers or charge-coolers.

The primary purpose of an intercooler is to cool down the compressed air before it enters the engine. This cooling process offers several important benefits:

Increased Air Density: Compressing air generates heat, and hot air is less dense than cooler air. By cooling down the compressed air, an intercooler increases the air density, resulting in a higher volume of air molecules in the same amount of space. This denser air contains more oxygen, leading to improved combustion and better engine performance.

Reduced Risk of Detonation: Cooler intake air helps prevent premature detonation or knocking. Detonation occurs when the air-fuel mixture ignites spontaneously before the spark plug fires, causing huge spikes in cylinder pressures and potentially damaging engine components.

Protection of Engine Components: Lowering the temperature of the air entering the engine will naturally lower the temperature inside the cylinder. This can reduce the heat stress on engine components such as pistons and valves.

Consistent Performance: Intercoolers help maintain much more consistent and stable engine performance, especially during prolonged periods of high-speed or high-load driving. Without an efficient intercooler set up a huge amount of heat can build up after just a couple of pulls.

Exhaust gas heat

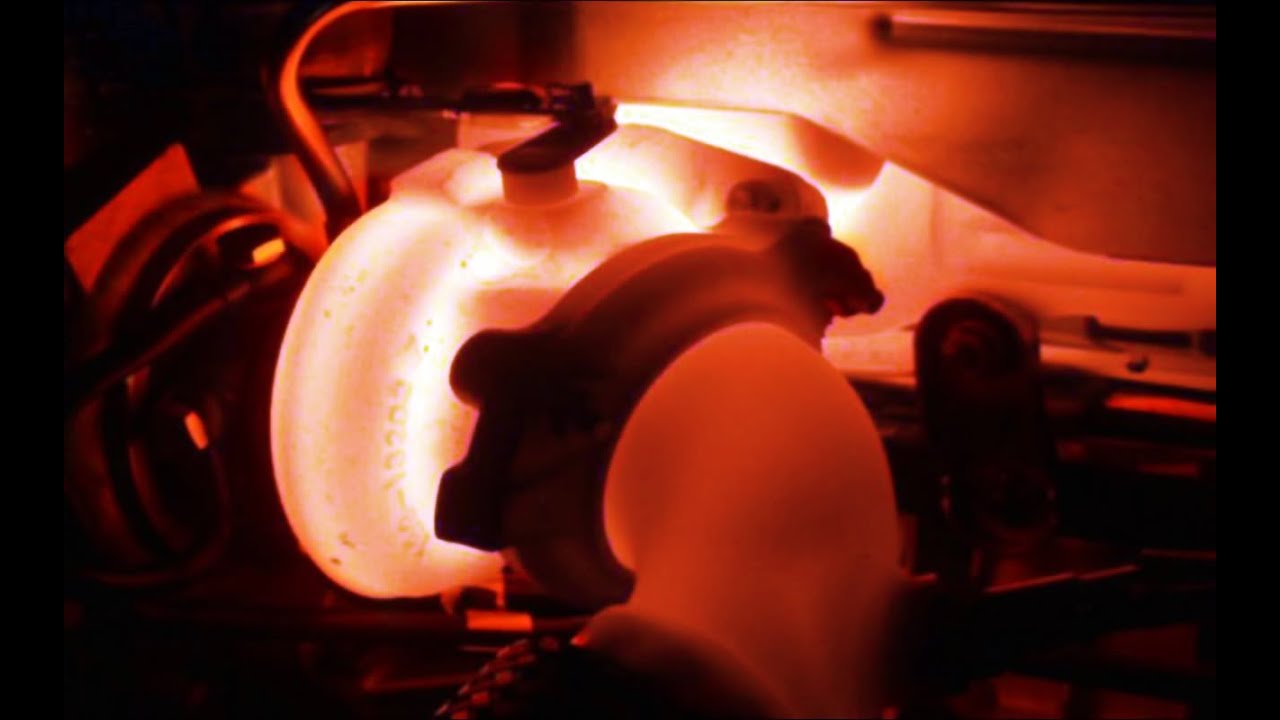

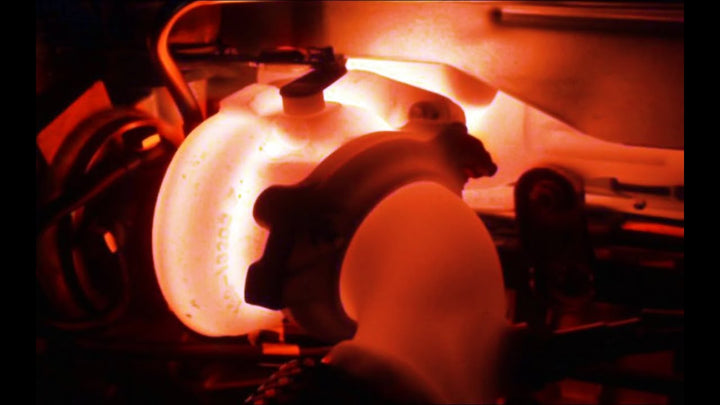

We've all seen pictures and videos of turbos glowing red after some spirited driving, this is due to the high-temperature exhaust gases being forced through the small turbocharger, further elevating their temperature. If this intense heat is not effectively managed, it can rapidly lead to turbo damage, increased intake air temperatures (IATs), and a significant decline in engine performance. Proper heat management becomes crucial to preserving the turbo's health and maintaining optimal engine efficiency.

Modern turbochargers usually feature both oil and water cooling systems to ensure effective heat dissipation and lubrication. These systems play a crucial role in keeping the turbo within its ideal operating temperatures, provided the rest of the cooling system can handle the heat load. As the intense heat from the turbocharger transfers to the coolant and oil, the efficiency of radiators and oil coolers becomes paramount in dissipating this heat away effectively.

Performance radiators: Upgraded radiators from the likes of Airtec, CSF and Pro-Alloy all feature larger and more efficient cores, ensuring better heat transfer from the coolant system to the surrounding air. This enhanced design helps maintain more stable coolant temperatures, contributing to improved cooling performance.

Oil coolers: Most performance cars can accommodate additional or larger oil coolers, functioning on the same principle as performance radiators by effectively transferring heat away from the oil and dissipating it into the surrounding air. This helps maintain optimal oil temperatures and enhances the overall cooling capacity of the engine's lubrication system.

Heat shielding: In a lot of engine bays, space is often limited, and turbochargers can be positioned very close to other engine components. To prevent potential damage from that glowing red turbo, it is crucial to take measures to contain the heat within the turbo and exhaust system. Heat shields, exhaust wrap, and ceramic coating are effective solutions for this purpose, ensuring that the intense heat remains confined and does not adversely affect surrounding engine components.

So, that concludes our brief overview of cooling your turbocharged car. While there is much more detail to explore, I hope you found this information helpful.

We have a comprehensive range of high-quality cooling solutions for a range of makes and models available. Feel free to reach out and ask our team for advice on the best options for your specific needs.

Until next time!

Chris

https://www.wayside-performance.co.uk/collections/cooling